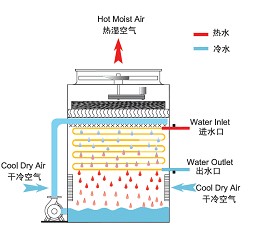

Compact structure

Countercurrent tower structure is compact, saving space; and spray water and air are reverse flowing, than the cross-flow heat transfer has a larger temperature difference or enthalpy and is conducive to improve heat exchanger performance. As air intake on all sides, can not subject to site constraints, a higher elasticity.

1.SUS316L Heat exchange coil/hot dip galvanized heat exchange coil

For heat exchange, the first need is the heat transfer area, therefore division coil adopts the oval cross structure (long side 31.75 mm, short edge is 21.59 mm), there are plenty of heat exchange area, The heat exchange efficiency has a fundamental guarantee ; Stainless steel pipe/hot dip galvanized steel pipe, thickness of 1.0/1.5 mm, overall anticorrosive performance is remarkable. Coil adopts argon arc welding, welding design pressure 1.6 MPa. Plate of control as a process, every single coil through strict test pressure is 2.5 Mpa, after assembly as a whole coil pass an 2.5 Mpa air tightness test, to ensure that the coil of the compression performance. In and out of the water pipe connection for DN100 stainless steel flange, convenient installation and disassembly.

2.Effect of return air is good

The hot air Is not easy to return, because the inlet and the outlet are far apart.

3.Dual channel into the wind column

3. The air inlet grille is made of corrosion resistant PVC. It is designed as "opaque" double channel , reducing spillage and decreasing the possibility of the algae generated. In ventilation window equipped with stainless steel wire mesh on both sides at the same time, The service life of the increase in sand areas. Improvement plan: in the future upper grille retaining flange can be widen and make angle adjustment. Sealing treatment for sheet metal seams with glass glue , prevent spraying water penetration from the inner wall of the tower into upper grille.

4.Accessible water tray

Available to enter from all sides of the water tray, open area simplifies maintenance, also can check the disk when water pump under operation.

5.Spray water distribution system:

Shanghai TYACHT unique spray water system not only guarantee enough water, also ensure the uniformity of spraying water, and water spray adequately and evenly scattered on the coil , finally ensure that heat transfer performance of the equipment.

6.Dedicated the desilting port:

Mainly used for fast desilting of cooling tower sump during sandstorm season .Desilting port is located in the bottom of the sumps at the lowest, convenient maintenance for workers to sweep sediment directly from the cooling tower; sand removing time and workload reduced during sand season and desilting time shortened from 40 minutes to 15 minutes

7.Compressed air interface:

Mainly used for rapid emptying of the cooling tower heat exchanger coil. Compressed air interface in the top inlet of the heat exchanger coil , threaded connection. Facilitate the rapid pressurization operation when drainage maintenance and winter shutdown drainage operations ; drainage time from 45 minutes to 8 minutes; while avoiding the drainage process hanging ice and drainage without a net.

Optional components

1.Access Ladders

Designed access ladder features a sloped “ships type” ladder arrangement which provides fast and easy access to the water distribution system and drive components. The ladder(s) will transport separately and must be field mounted.

2.Working Platform & Ladder with Davit

To maintain fan motors and water distribution system easily, an operating platform ( made of overloading galvanized steel plate)and a ladder can be installed. Hanger can help to move the motor. Motor davit and bracket are made of overloading galvanized steel bracket, which installed at the side of the unit.

3.Stainless Steel Water Basin

Modular design, stainless steel material water tray as contact parts with water, including the bracket and the grille frame of the unit, has the characteristics of corrosion resistance ability.

4.Finned coil

Spiral finned heat exchange coil can be used to increase the dry run ability of the unit. It can be used in a cold environment, or in wither when require small operation load . Plate number of finned tube and fin number can be adjusted according to the operation condition of the dry run.

.jpg)

5.Exhaust hood with a closed throttle

When closed cooling tower used in the water - air heat pump system, or some sort of process cooling application, use optional machine - exhaust hood with closed damper can reduce heat loss of equipment during idle period in winter.

6.Gear Drive System

The Gear Drive System has been carefully designed to provide long life and troublefree operation, even in severe duty cooling tower applications. The Gear Drive System is designed with a minimum 2.0 service factor and meets or exceeds AGMA and CTI gear drive standards.

7.Electric Heaters

When the fan off, and the ambient temperature is not lower than 0 º F (-18 º C), it can keep water temperature in the water tray above 40 º F (4.4 º C) . Electric heater furnished with a low water protection device, and will only start when it immersed in water . All components are mounted within housing to accommodate outdoor application.Electric heater relay switch and the wire is not included in the standard configuration .

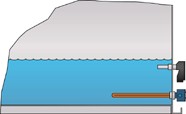

8.Electric Water Level Control

Available with an optional electric water level control system in place of the standard mechanical float valve and makeup assembly. This package provides very accurate control for the basin water level and does not require field adjustment, even under varying operating conditions.

9.Other optional parts

Hot Water /Steam heat exchanger Coils

Steam ejector

Vibration switch

Remote tank

Automatic load or more options, please inquire factory